The Visibility Principle

Why Seeing Beats Building in Digital Transformation

Why it matters: Across manufacturing, retail, healthcare, and government, organisations achieving 12-35% ROI share one trait: they prioritised real-time visibility over comprehensive technology replacement. The implication for UK mid-market leaders is clear—your next transformation investment should measure before it builds.

Join The Control Layer for weekly perspectives on AI, cybersecurity, and building technology that serves human purpose.

The pattern hiding in plain sight

Something counterintuitive emerged from the past week’s digital transformation data. The organisations delivering measurable returns—30% reduction in unplanned downtime at VINOVALI, 63% diagnostic improvement in UK healthcare, 13 million users on GOV.UK One Login—didn’t deploy the most sophisticated technology. They deployed the most visible.[1][2][3]

This isn’t semantic wordplay. It’s a strategic distinction with budget implications.

Manufacturing execution systems that delivered 35% ROI within 90 days didn’t automate decision-making. They automated measurement. Retail automation that freed staff for high-value work didn’t replace humans. It offloaded transaction tracking so humans could focus on customers. Government platforms that scaled to millions didn’t build monolithic systems. They built componentised visibility layers—identity, access, AI-assisted navigation—each measurable independently.[1][4][3]

The principle is simple: you cannot optimise what you cannot see. And you cannot see what you’re not measuring.

What the data actually shows

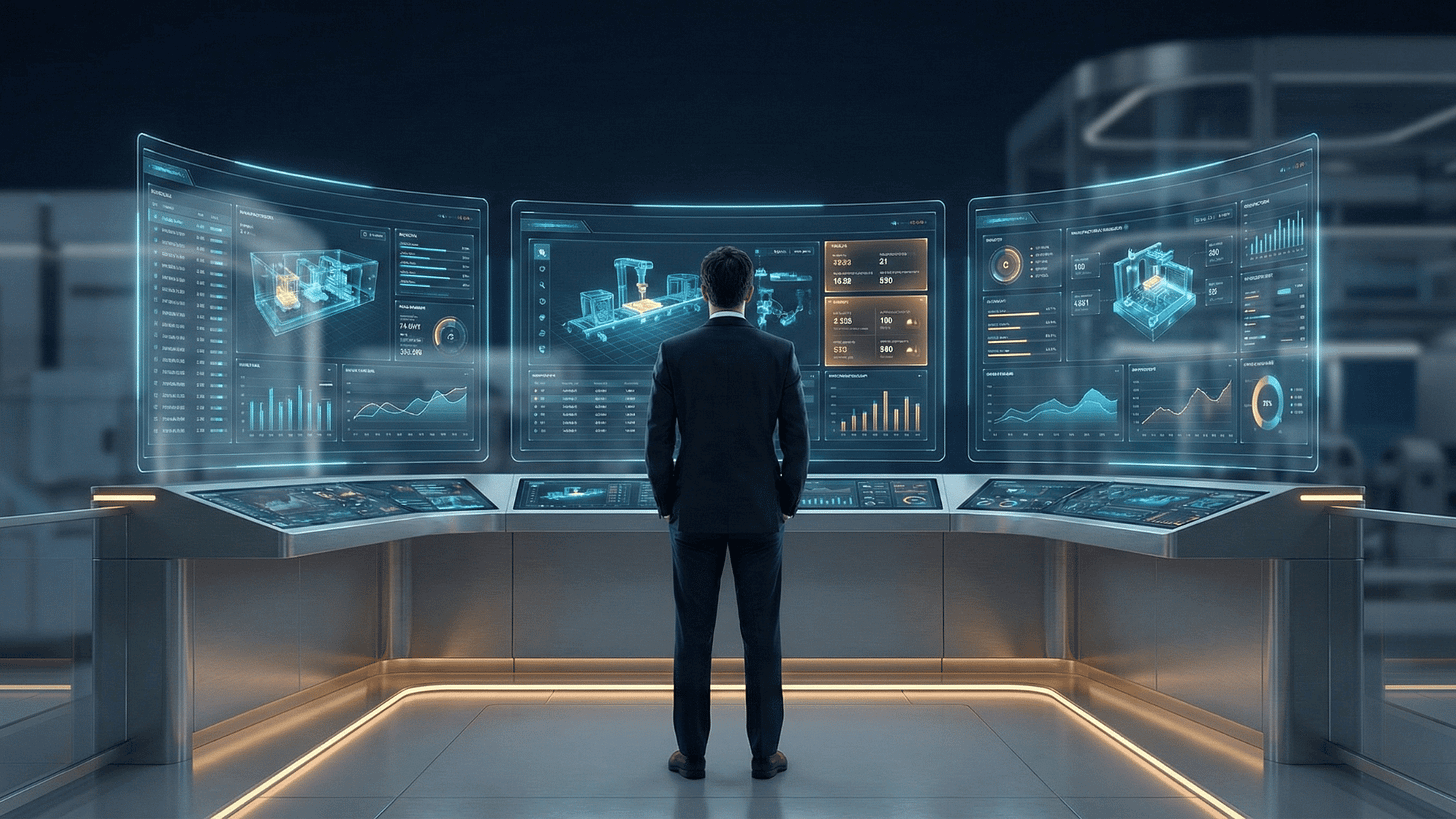

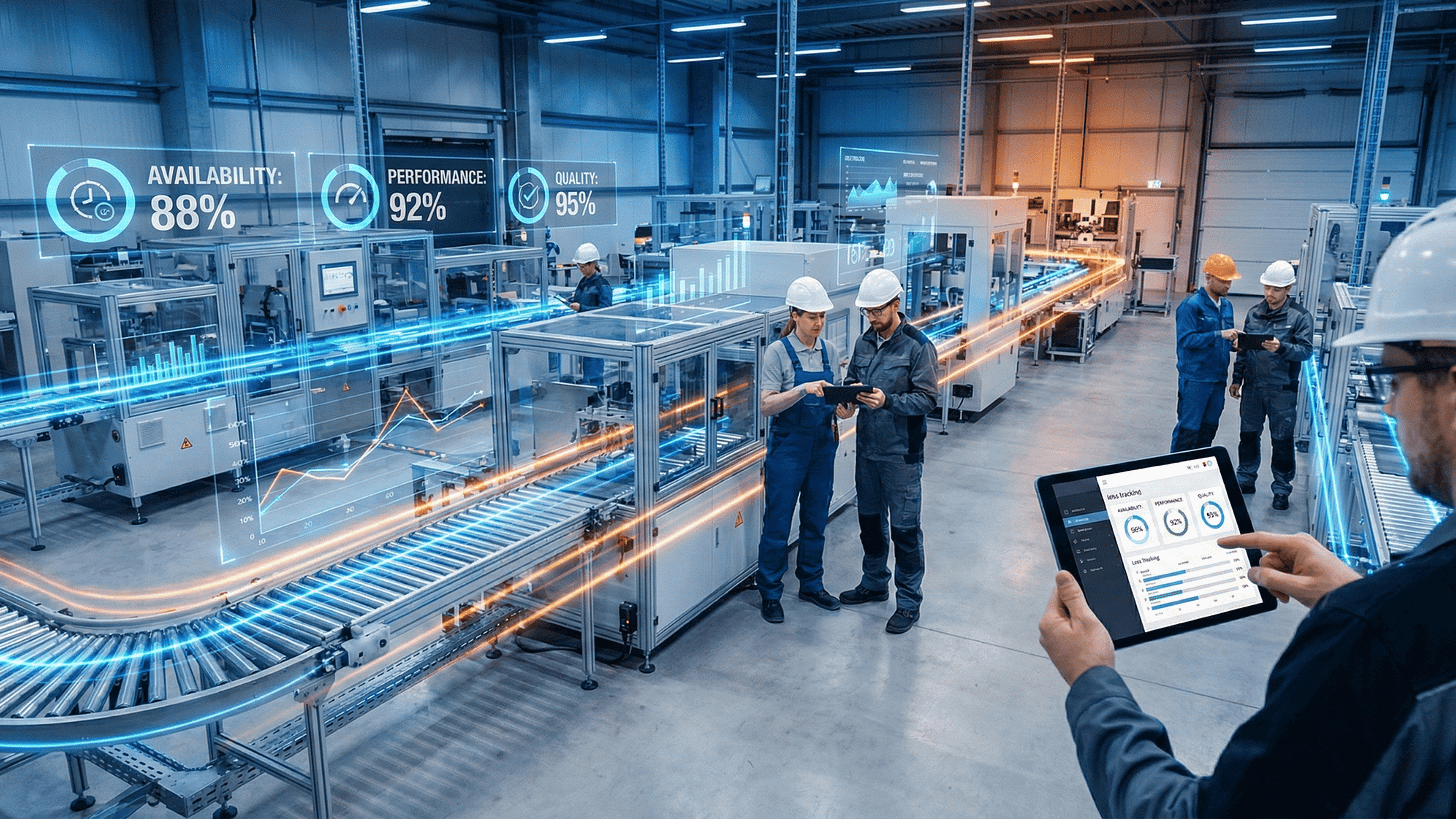

Manufacturing: From guesswork to discipline

VINOVALI, a French food manufacturer, achieved a 30% reduction in unplanned downtime within six months of deploying a cloud-based manufacturing execution system. The technology wasn’t revolutionary. The discipline was.[1]

Before deployment, production and maintenance teams operated on assumption. Losses were considered structural—”that machine always runs hot”—rather than addressable. The MES didn’t introduce new equipment. It introduced loss tracking. Real-time. Automated. Unambiguous.

Once loss patterns became visible, maintenance teams shifted from reactive troubleshooting to predictive intervention. The 30% downtime reduction emerged not from capital investment but from what one implementation partner calls “visibility discipline”—the organisational habit of acting on measured loss rather than assumed loss.[1]

Across hundreds of UK manufacturing deployments, a consistent pattern emerged: 15% operational efficiency gains and two hours daily saved per operator. Not from automation. From eliminating manual spreadsheet reconciliation and decision delays inherent to batch-based reporting.[1][2]

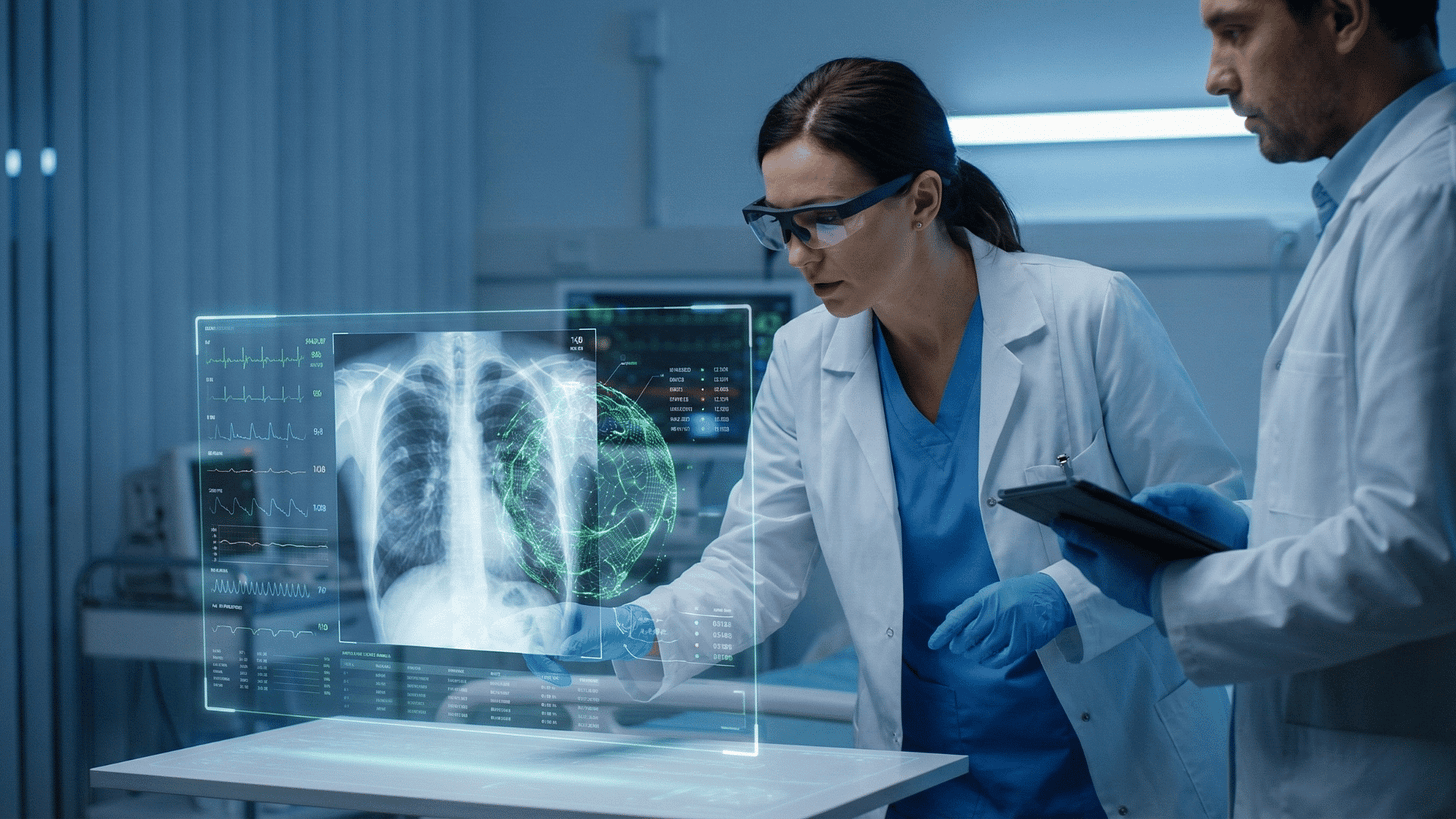

Healthcare: Augmentation over automation

A UK healthcare provider achieved 63% improvement in diagnosis rates through machine learning-based patient monitoring. The instinct might be to credit the algorithm. The reality is more nuanced.[5]

Effective healthcare AI doesn’t automate diagnosis. It augments clinician capability. The 63% improvement reflects ML pattern recognition combined with human clinical judgment—reducing both false positives (purely algorithmic) and false negatives (purely human). The system made patterns visible. Clinicians made decisions.

This distinction matters for governance. Systems designed to replace human judgment face regulatory scrutiny, clinical resistance, and liability questions. Systems designed to make patterns visible face adoption curves.

Retail: Labour redirection, not labour replacement

UK retailers deploying automation reported benefits within 6-12 months, but the metrics that mattered weren’t pure cost reduction. They were operational resilience and customer loyalty.[4][6]

Retailers facing structural labour shortages shifted staff from transactional roles—checkout, basic inventory—to specialist activities: customer consultation, loss prevention, brand engagement. The automation handled routine measurement and tracking. Humans handled exceptions and relationships.

The business outcome: 53% of customers say they’d avoid retailers who fail on order accuracy. Automation that enables accuracy while freeing humans for relationship-building isn’t efficiency theatre. It’s competitive positioning.[4]

Government: Components over monoliths

The UK Government Digital Service published its Roadmap for Modern Digital Government on 26 January 2026, revealing the architecture behind one of the world’s most mature citizen-facing digital platforms.[3][7]

GOV.UK didn’t build a monolithic system. It built visible, measurable components:

GOV.UK One Login: 13 million users accessing 120+ government services through a single authentication layer

GOV.UK App: 316,000 downloads by December 2025, providing unified mobile access

GOV.UK Chat: AI-assisted navigation rolling out across all GOV.UK properties in 2026

Each component is independently deployable, independently measurable, and independently improvable. The strategy prioritises reduced friction over feature maximisation. Citizens experience fewer logins, simpler navigation, and 24/7 AI support—not because of technological sophistication but because of architectural visibility.[3][7]

Analysis: The visibility-first framework

Three implementation patterns distinguish organisations achieving measurable ROI:

Pattern 1: Measurement precedes automation. Every successful case study began by making losses, inefficiencies, or friction visible before attempting to address them. Manufacturing MES tracked losses before optimising production. Retail automation measured transaction patterns before reallocating labour. Government platforms measured user journeys before simplifying authentication.

Pattern 2: Human judgment remains central. Systems that preserved human decision-making while automating measurement achieved faster adoption and higher outcomes than systems designed to automate decisions. Healthcare AI augments clinicians. Retail automation frees staff for customer engagement. Government Chat assists navigation rather than replacing it.

Pattern 3: Phased implementations outperform big-bang deployments. Manufacturers starting with single-line MES pilots delivered 12% ROI within 30 days, 25% by day 60, and 35% by day 90. Retailers deploying store automation in phases reported benefits within 6-12 months. Government platforms scaled through componentised architecture. Big-bang approaches faced 45% adoption rates versus 85% for phased rollouts.[1][2]

Risks and constraints

The visibility principle isn’t a silver bullet.

Data quality remains the bottleneck. Visibility into bad data produces confident wrong decisions. Manufacturing MES implementations assume sensor accuracy. Healthcare AI assumes clean patient records. Government platforms assume identity verification integrity. Each assumption carries risk.

Cultural change is harder than technology change. VINOVALI’s 30% downtime reduction required production and maintenance teams to align around data-driven decisions rather than assumed losses. Not every organisation has the leadership alignment to make that shift.

Vendor lock-in risks compound with componentisation. GOV.UK’s componentised architecture is elegant, but each component creates a dependency. Organisations adopting similar approaches must consider exit strategies alongside entry points.

Compliance creates new visibility requirements. NIS2, the Cyber Security and Resilience Bill, and the EU AI Act all mandate visibility into systems, data flows, and decision processes. Visibility-first approaches align with these requirements, but compliance itself consumes resources.

What to do next

For boards and executives: Challenge any transformation proposal that can’t articulate what will become visible in the first 90 days. If the business case depends entirely on benefits realised after 18+ months, the risk profile is wrong. Phased implementations with early visibility milestones de-risk transformation investments and provide decision points for scaling or pivoting.

For technical leaders: Audit your current transformation initiatives against the visibility principle. Are you measuring before optimising? Are you preserving human judgment in decision flows? Are you deploying in phases that allow independent measurement? If not, consider restructuring.

For mid-market organisations: The visibility principle is your competitive advantage. You can’t outspend enterprise competitors on technology, but you can out-measure them on outcomes. Start with single-line pilots. Demand ROI measurement at 30, 60, and 90 days. Scale what works. Abandon what doesn’t. This is how 15% efficiency gains and two-hour daily savings per operator become your baseline, not your aspiration.[1]

Disclaimer: This article represents analysis based on publicly available information as of January 2026. It does not constitute legal, financial, or professional advice.

If your organisation needs support implementing visibility-first transformation frameworks, Arkava helps mid-market enterprises turn AI investment into measurable business outcomes.

References

[1] ITI Group. “Why Manufacturing Execution Systems should be first on an SME’s digital roadmap in 2026.” ITI Group, 21 January 2026. https://www.itigroup.com/why-manufacturing-execution-systems-should-be-first-on-an-smes-digital-roadmap-in-2026/

[2] Shoplogix. “Phased MES Implementation Approach: Your Step-by-Step Guide.” Shoplogix, 18 September 2025. https://shoplogix.com/phased-mes-implementation-approach/

[3] UK Government Digital Service. “Roadmap for Modern Digital Government.” Department for Science, Innovation and Technology, 26 January 2026. https://www.gov.uk/government/organisations/government-digital-service

[4] Retail Tech Innovation Hub. “New retail efficiency for 2026: transforming operations with AI automations.” Retail Tech Innovation Hub, 15 January 2026. https://retailtechinnovationhub.com/home/2025/12/16/new-retail-efficiency-for-2026-transforming-operations-with-ai-automations

[5] Rishabh Soft. “Top Digital Transformation Trends and Strategies for 2026.” Rishabh Soft, 7 December 2025. https://www.rishabhsoft.com/blog/digital-transformation-trends

[6] Conversations on Retail. “Why 2026 Is Emerging as the Year In-Store Automation Becomes Retail Infrastructure.” Conversations on Retail, 29 January 2026. https://conversationsonretail.com/why-2026-is-emerging-as-the-year-in-store-automation-becomes-retail-infrastructure/

[7] Government Digital Service Blog. “Our roadmap for modern digital government.” GDS Blog, 20 January 2026. https://gds.blog.gov.uk/2026/01/20/our-roadmap-for-modern-digital-government/

Wow, the 'measure before it builds' bit really stood out. This totally tracks with your earlier points about smart tech deployment. It's not about the fanciest stuff, but making sure you can *see* whats happening. Such a sharp take, as alway. Love it!

Outstanding framework! The "measurement precedes automation" principle cuts through so much transformation noise. VINOVALI's 30% downtime reduction from visibility alone is teh kind of ROI executives actually care about. The phased implementation contrast—85% adoption vs 45% for big-bang—mirrors what I've seen in mid-market deployments where betting everything on 18-month payoffs creates board panic halfway through. The componentised GOV.UK architecture is chef's kiss for anyone drowning in monolith regret dunno why more orgs don't copy that pattern.